Project Management

R&D System Process

Intellectual Property Management

Informatization Management

IPD Process

R&D System Process

Divide technology development into "basic technology research and development" and "product development", and vigorously develop disruptive "basic technologies"; We plan to carry out industry university research cooperation with multiple universities, promote research on various compressor basic technologies and product development, introduce high-end talents, and build an innovative technology research and development team.

Intellectual Property Management

The company has established a full-lifecycle management system certified to GB/T29490, covering patent, trademark, and trade secret protection. The system includes regulations such as the "Intellectual Property Reward and Punishment System" and "Emergency Response Plan"; it uses the Zhihuiya system to monitor infringement risks, enabling mandatory patent prediction for R&D projects, rapid response to infringement, and efficient transformation (e.g., the double helix technology reduces consumption by 8%, resulting in annual benefits in the hundreds of billions), with a patent transformation rate exceeding 60%.

Informatization Management

Integrating CAE tools such as SolidWorks with the PLM system as the core, connecting design data with the ERP production system to ensure data consistency; developing an intelligent control system for the air compressor station, using the Internet of Things to monitor equipment status in real time, and reducing operating costs by 20%; simultaneously building a collaborative network of industry, academia, and research (such as the Xi'an Jiaotong University Joint Laboratory), and promoting technological cooperation and talent introduction in stages.

IPD Process

A six-stage structured process (concept → lifecycle) is adopted, with a dual-team mechanism of IPMT (Investment Decision) and PDT (Cross-departmental Execution). Risks are controlled through 5 decision review points (DCP). Market orientation drives 75% of resources towards energy-saving products (such as Class 1 energy efficiency air compressors), and an asynchronous development model is used to reuse 70% of common modules, shortening the development cycle by 40%.

Product development

Innovative achievements

Focus on cultivating product brands, responding to the "dual carbon" goal, taking the lead in implementing energy efficiency labels, 367 products are registered on the China Energy Efficiency Labeling Network, including 173 first-class energy efficiency products and 121 second-class energy efficiency products. The performance indicators exceed national standards, reaching the domestic leading level and approaching the international advanced level; compile and implement the "Enterprise Standard" to improve product technology.

Product Types

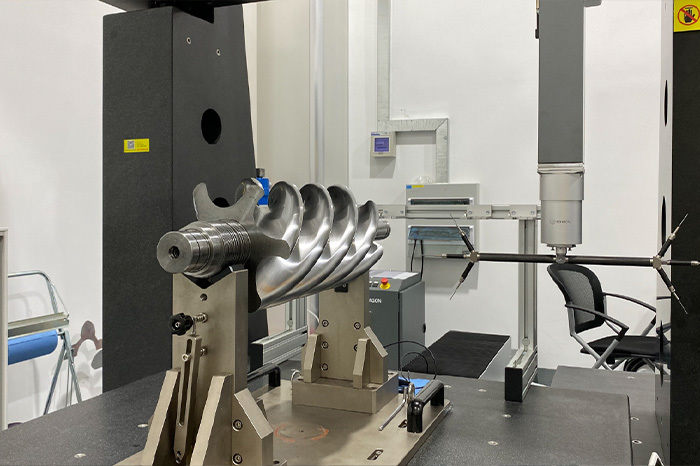

The production covers more than 300 specifications of air compressors of various specifications and varieties, including air-cooled (water-cooled) screw type, high-power and large-capacity, variable frequency type, etc. Many products have passed GC energy-saving certification and are widely used in many industries. Some products fill the domestic technical gap and break the foreign monopoly.

Recent Projects

In compressed air system equipment, it has the ability to independently design screw profiles to improve the efficiency of the main engine; the whole machine design adopts high-efficiency motors and frequency conversion technology to launch T3851 series energy-saving two-stage compression products; in terms of information technology, it develops an intelligent air compressor station control system; in the field of centrifugal and air suspension centrifugal machines, it adopts advanced technology to reach the world's leading level.

Basic research and development

Long-term Planning

Divide technology development into "basic technology research and development" and "product development", vigorously research disruptive "basic technologies"; focus on developing core technologies for double-helix compressors, researching compressor-related characteristics from macroscopic and microscopic perspectives to improve performance and reduce energy consumption; plan to carry out industry-university-research cooperation with multiple universities to promote the research and development of various compressor basic technologies and products, introduce high-end talents, and build an innovative technology research and development team.

Technological Innovation System

With the company's technology center as its core, adhering to the principles of "winning through quality and differentiation", and upholding the corporate philosophy of commitment to energy-saving innovation. R&D expenses account for more than 5% of sales revenue. We collaborate with Xi'an Jiaotong University on industry-academia-research cooperation, focusing on basic technology research and development, such as rotor profiles, magnetic levitation and air levitation technologies, high-efficiency liquid-cooled motors, etc., to ensure technological leadership.

Intellectual Property System

Establish and improve a stable and operational intellectual property rights system, obtain GB/T29490-2013 Intellectual Property Management System certification, and be recognized as a demonstration enterprise for patent work in Jiading District. This includes a series of systems such as the "Enterprise Intellectual Property Management System", achieving full-process management of intellectual property rights and enhancing protection capabilities.

R&D equipment