- All

- Product Management

- News Information

- Introduction Content

- Company Network

- FAQ

- Company Video

- Company Album

Product Description

UNITED OSD two-stage VPM screw air compressors adopt permanent magnet synchronous motors, which require no excitation current, offer high efficiency, and have no reactive power loss. The two-stage compression speed is high, and after frequency conversion, the air supply pressure range is wide and stable. The most obvious advantages are energy saving, large air output, and real-time adjustment of air intake according to air demand, ensuring more efficient operation of the air compressor.

Mechanical System

Air End

- Combining advanced rotor sealing and fluid dynamics technology, as well as the rotor profile, ensures high thermal insulation efficiency at all levels of the rotor, enabling each air end to achieve better performance;

- Utilizing bearings with greater load capacity, precise calculation of bearing installation and preload, enhancing reliability and extending bearing service life;

- The main unit casing adopts a unique geometric tolerance evaluation system and high-precision CNC machining technology, strictly controlling the internal clearance of the main unit, making the main unit efficient while maintaining high reliability;

- The main unit adopts two-stage compression and inter-stage cooling, resulting in higher comprehensive adiabatic efficiency and achieving energy-saving goals;

- Compared to single-stage compressors, two-stage compressors can save up to 10%-25%.

Power Transmission System

- The drive motor is directly connected to the two-stage compression main unit without a coupling, resulting in a maintenance-free transmission chain and a 1% reduction in energy consumption;

- The IP55 fully enclosed motor and main unit casing are integrated, effectively preventing metal particles, dust, moisture, and other pollutants from entering the motor and main unit, making the compressor performance more stable;

- The motor bearings use reinforced cylindrical + ball bearings, offering higher strength and reliability;

- Transmission gears with machining precision reaching aerospace level 6, multiple heat treatments, and related processing techniques ensure all mechanical components have superior surface hardness, ultra-high wear resistance, and yield strength;

- Independent oil supply system and precise oil filtration effectively ensure the stability and reliability of the entire gearbox during long-term full-load operation.

Air Intake and Filtration System

Pre-filter protective layer:

Prevents large dust particles, cotton, and other debris from entering the air compressor. Keeps the compressor interior clean. Strictly observes the first pass of compressed air.

Particulate Air (HEPA) Filtration:

Heavy-duty air filtration system with a filtration accuracy of up to 99.9% for particles larger than 3μm. Suitable for various heavy dust environments.

Dual large-diameter air intake assembly design:

The pressure difference across all air paths is less than 0.2bar, significantly extending the service life of the air filtration system.

Optimized design of large-diameter intake valve:

Low energy consumption during no-load operation, cast aluminum material, more stable performance.

Optimized mold design for air intake pipe:

High-strength rubber seal, strong and durable.

Oil filter:

Donaldson oil filter, high clean filtration level, effectively protects the safe operation of the main unit bearings, and extends the service life of the main unit.

Oil-air separation system:

European-designed oil-air separation element, fiberglass filter material, long life, higher efficiency, no frequent replacement required. The coalescing separation element works in conjunction with the oil return device to effectively recover and circulate lubricating oil, preventing oil overspray and ensuring the compressor exhaust oil content is ≤2ppm.

Lubricating Oil:

UNITED OSD lubricating oil has many characteristics such as good oxidation resistance, high temperature resistance, high flash point, and excellent thermal conductivity.

Cooling System

- Heat exchange design margin is 20%-50%, ensuring stable operation of the compressor in extreme environments and minimizing pressure drop.

- Standard motor frequency conversion, accurate oil temperature control; further reduces air compressor energy consumption.

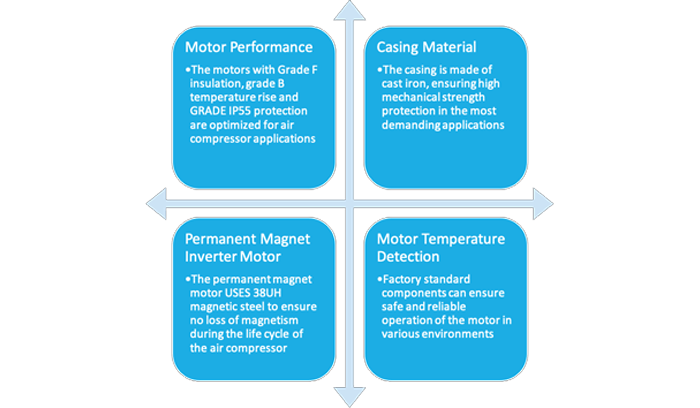

Features of Permanent Magnet Synchronous Motor (PMSM)

- Motor efficiency up to 96%, power factor 0.98, far exceeding Level 1 energy efficiency standards;

- High coercivity, high temperature resistant permanent magnets, ensuring no demagnetization at 180℃ high temperature;

- Independent fan cooling ensures safe operation of the motor for long periods and at low frequencies;

- F-class insulation, 70K temperature rise design, suitable for high-temperature conditions of air compressors;

- Fully enclosed IP55 protection, protecting the internal environment of the motor, extending the life of permanent magnets and insulation;

- Built-in temperature protection, protecting winding insulation and permanent magnets.

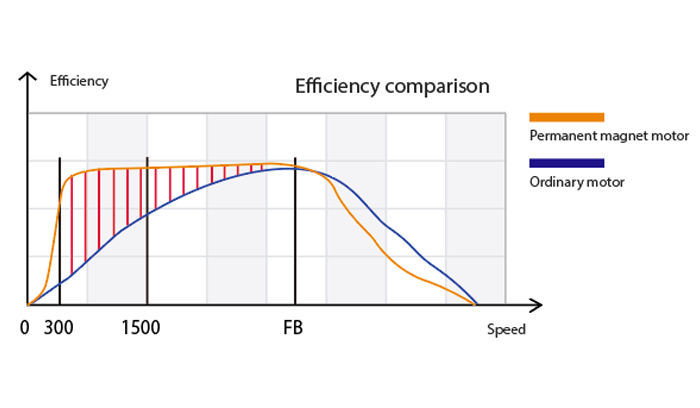

Permanent Magnet Synchronous Motor Vs. Ordinary Asynchronous Motor

Efficiency:

Eliminates excitation system losses, improving efficiency.

Maintenance under low load conditions:

PMSM's energy efficiency is more than 9% higher than asynchronous motors and remains constant as the frequency decreases.

Large starting torque:

The maximum starting torque of permanent magnet synchronous motors can be up to 3 times the rated torque, while general asynchronous motors are only 1.6 times.

More stable control:

PMSM response time is less than 50ms. Air output can be instantly adjusted over a wide range to precisely stabilize air pressure.

Features of UNITED OSD VFD Variable Speed PMSM Air Compressor

- Ultra-low temperature rise design allows the compressor to run stably at low frequencies for extended periods;

- Adopting an open-loop vector control system, the control speed is faster and speed regulation is more accurate;

- The compressor unit can still operate when the frequency drops by more than 50%;

- Stable pressure, with pressure fluctuations precisely controlled within 0.01mpa; Possesses soft start characteristics, avoiding inrush current impact and reducing startup energy consumption.

Two-stage VPM (VFD+PM) Screw Air Compressor

Contact Us

mail@sunc.cn

021-69176699