- All

- Product Management

- News Information

- Introduction Content

- Company Network

- FAQ

- Company Video

- Company Album

| Working Pressure | 2-10[bar] | 29-145[psig] |

| Working Air Capacity | 5.3-80[m³/min] | 187-2825[cfm] |

| Working Power | 37-500 [kW] | 50-670[hp] |

Why Choose UNITED Oil-Free Screw Air Compressor

Energy Saving

- Hitachi Technology - better interprets the logical function of energy saving.

- TUV Certified Class 0

Optimized Operating System

- The feature-rich ITCS controller makes operation more effortless and time-saving. A simple connection allows for the joint control of 2 air compressors.

- Multiple air compressors are centrally controlled through multiple controllers.

Thermosetting Coating

The rotor surface and inner wall of the casing are coated with molybdenum disulfide thermosetting coating. By controlling the clearance, it effectively prevents corrosion and reduces internal leakage.

Easy Maintenance

Easy to maintain, with long service intervals.

Environmental Care

An oil mist cleaner, as a standard configuration, can relieve pressure inside the gearbox and ensure the workshop's cleanliness.

Low Noise

Reduces pulsating noise and improves sound quality.

Industry Applications

Food and Beverage Industry

The high-temperature compression environment of oil-free air compressors reduces the microbial content in the compressed air. Additionally, the entire compression process is oil-free, significantly lowering the risk of food and beverage product contamination during production.

Pharmaceutical Industry

The demanding pharmaceutical industry uses 100% oil-free compressed air throughout its manufacturing process. The quality of compressed air is an important part of GMP certification.

Chemical Industry

For applications in the chemical industry, from the first step of the production process to semi-finished products and then to the formation of final products, high-purity compressed air must be used at every step to minimize the risk of production shutdown.

Power Industry

The quality of compressed air is crucial and must not be overlooked. Therefore, when compressed air is applied to instrumentation in power systems, most designers choose oil-free air compressors.

UNITED Compressor Core Advantages

Hitachi Design

Dry compression means the compressed air is 100% oil-free because there is no lubricating oil in the compression chamber. The shaft seal ring is made of stainless steel and does not generate carbon dust.

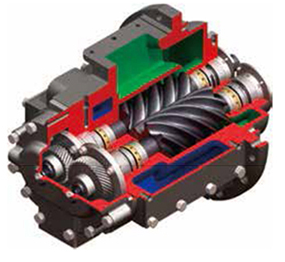

Hitachi Air End

Imported original Hitachi main unit ensures high quality and high performance.

Two-Stage Compression

The reduction in specific power with two-stage compression improves cooling performance, reduces internal compression management, and boosts performance by 5-10%.

Dry Oil-Free Technology

Since the advent of UNITED oil-free screw air compressors, over 100,000 pairs of oil-free rotors have been produced and applied in various industries, mainly pharmaceuticals, food and beverages, electronics, and industries with high compressed air quality requirements.

Oil-free Fixed Speed Screw Air Compressor

Contact Us

mail@sunc.cn

021-69176699

Category: