- All

- Product Management

- News Information

- Introduction Content

- Company Network

- FAQ

- Company Video

- Company Album

| Working Pressure | 7-12.5[bar] | 102-181[psig] |

| Working Air Volume | 0.61-72.3[m³/min] | 21.54-2553.25[cfm] |

| Working Power | 5.5-400[kw] | 7.38-536.41[hp] |

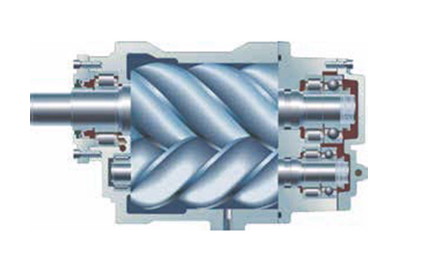

Energy-saving Air End

- The UNITED OSD air end is highly recognized in the air compressor industry for its exquisite design and precise manufacturing.

- It adopts large-diameter screw rotors with a balanced length-to-diameter ratio, optimized for greater efficiency based on the new fourth-generation rotor profile, achieving optimal performance for contact surface, contact line, leakage triangle, and fluid dynamic characteristics of the rotor,

- further improving volumetric efficiency. The screw rotor thus has high adiabatic efficiency and low power consumption.

- Adopting imported large heavy-duty bearings and a unique bearing layout, while ensuring bearing rigidity, it significantly increases load capacity and extends service life, maintaining high reliability even under extreme conditions.

- The helical groove lip seal combined with a shaft sleeve made of high-grade bearing steel ensures the wear resistance of the shaft seal and shaft sleeve. The shaft seal has a pumping function, high reliability, and anti-leakage properties.

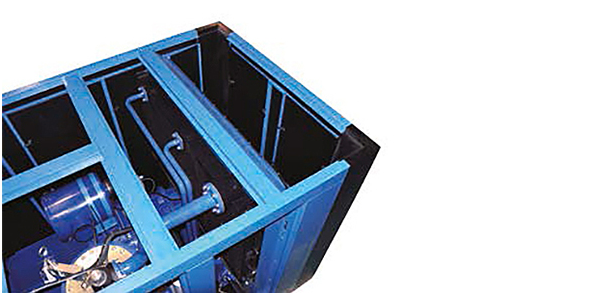

Cabinet Structure Design

The cabinet structure is divided into a cooling chamber and a heating chamber, providing better heat dissipation. All functional components are located in the cooling section to extend their service life.

The reasonable layout design has obtained a national patent, integrating electrical mechanisms for easy operation and installation without the need for on-site foundations. Internally, the cooling chamber and heating chamber do not affect each other, expanding the internal space of the cabinet. Optimized internal air circulation ensures comprehensive cooling of all functional components, extending their service life. The exterior adopts a closed, detachable box, with built-in high-quality flame-retardant sound-absorbing sponge, effectively reducing noise.

This structural design meets environmental protection requirements and is easy to maintain.

Wearing Parts

Particulate Air (HEPA) Filter:

Heavy-duty air filtration system, with a filtration accuracy of up to 99.9% for particles larger than 3μm. Suitable for various heavy dust environments.

Oil Filter:

Donaldson oil filter, high clean filtration level, effectively protects the safe operation of the air end bearings and extends the service life of the air end.

Oil and Gas Separation System:

European-designed oil and gas separation element, glass fiber filter material, long life, higher efficiency, no frequent replacement required. The coalescing separation element works with the oil return device to effectively recover and circulate lubricating oil, preventing oil overflow and ensuring compressor exhaust oil content ≤2ppm.

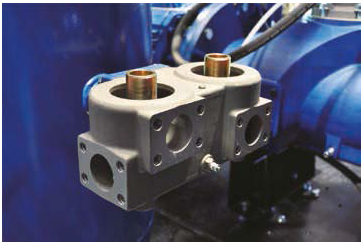

All-new Temperature Control and Oil Filter Combination Valve

This patented design integrates the temperature control valve and oil filter valve, making internal piping connections simpler, with fewer leakage points, reducing the incidence of failures. More importantly, it further reduces pressure drop, is more energy-efficient, and avoids obstacles such as pipe vibration, breakage, and leakage that occur when the oil filter base and temperature control valve are installed separately.

Temperature Control Valve

Powered by British AMOT

Precisely controls the oil return temperature at 65℃. If the oil return temperature is too high, it will damage the oil film, leading to oil deterioration, reduced cooling and sealing properties, and rapid carbon accumulation; if the oil temperature is too low, water will separate from the air, the oil will emulsify and deteriorate, affecting the service life of the air end. Therefore, the temperature control value is a key guarantee for the stable operation of our compressor.

EPC Intelligent Control System

UNITED OSD compressors are equipped with an Electronic Pressure Controller (EPC) to ensure automatic and intelligent operation of the machine. The intake valve controls the exhaust pressure between the upper and lower limits of the preset pressure by detecting sensor data such as exhaust pressure and temperature, outputting stable pressure. When the compressor idles for too long, the system will automatically shut down and restart when air supply is needed, which can both output constant pressure and achieve energy-saving purposes. At the same time, the system can quickly diagnose all on-site faults during operation, maximizing the reliable operation of the compressor and extending its service life.

Local Control

- Chinese and English display languages, touch buttons, intuitive, fast, and convenient menu operation.

- Users can preset and control delay times for star-delta switching, start-up, loading, shutdown, overpressure, etc., during operation.

- Allows users to view and manage on-site faults.

- Users can store and search historical faults by classification type and occurrence count.

- Users can store and search historical faults by classification type and occurrence count.

- Users can accumulate and store running time, loading time, unloading time, and filter service time.

- Users can view all preset parameters and accumulated times at any time during operation.

- Users can modify and store parameters to preset values as needed.

Linkage Control

Users can set one compressor as the master and one or more compressors (up to 16) as slaves or standby units to form a multi-compressor linkage control system.

Using EPC, it automatically adjusts the start-stop sequence of each compressor, balances the accumulated working time of each compressor, and ensures economic and stable air supply.

Remote Control

The Distributed Control System (DCS) remotely controls power on, power off, fault output, and early warning signals through passive dry contacts.

Master Computer Control

- The master control computer remotely interlocks and controls two or more compressors, collects and displays on-site signals, coordinates control and computer operation. By setting host computer parameters, users can obtain comprehensive management of the compressor unit at any time and obtain stable compressed air within the set pressure range.

- Collect and display a large amount of on-site data

- Vivid graphical interface

- Vivid graphical interface

- Record important data into the database.

- Automatically generate data history reports for future analysis.

- Compressor controller operating parameter settings.

- Trend curves for parameters such as pressure and temperature.

- Real-time and historical alarms.

- Operation is permission-secured. A password is required for basic operations.

- Single compressor unit test.

- Reminder for maintenance or replacement of compressor wearing parts.

*UNITED OSD COMPRESSOR provides various PLC system centralized control solutions according to users' actual needs, realizing human-machine interface through IPC, LCD, and configuration software, and communicating with DCS in the user's system for remote monitoring, with the following advantages: multi-link control and independent robust development capabilities.

Patent protection.

Through continuous R&D investment, the pace of product development and new technology application has accelerated. Currently, UNITED OSD has registered nearly a hundred national patents, covering key compressor technologies, integrated layouts, and integrated improvements of parts. These patents address a series of compressor issues, such as internal temperature rise under different operating conditions and maintenance difficulties. Through unique design and integration, the equipment can better meet usage and service requirements, comply with environmental protection requirements, and fully demonstrate the excellent quality of the products.

Quality assurance.

In 2003, UNITED OSD Compressor passed ISO9001 Quality Management System and ISO14001 Environmental Management System certifications. The company strictly adheres to Crosby's "Do It Right the First Time" quality requirements, insists on the "zero defect" work standard, and takes "producing defective products is unethical" as the measure of quality. UNITED OSD has always been committed to continuous product improvement.

Single-stage Fixed-speed Screw Air Compressor

Contact Us

mail@sunc.cn

021-69176699

Category: