- All

- Product Management

- News Information

- Introduction Content

- Company Network

- FAQ

- Company Video

- Company Album

| Working Pressure | 7-10 [bar] | 102-145 [psig] |

| Working Air Capacity | 1.65-70.3 [m3/min] | 58-2483 [cfm] |

| Working Power | 11-355 [kw] | 15-476 [hp] |

Product Description

UNITED OSD single-stage variable frequency screw air compressor UD-VFD series adopts vector control technology, ensuring small motor temperature rise, obtaining suitable torque within a wide speed range, and driving the air compressor to operate stably.

Vector control technology separately controls the excitation and torque two vectors of the stator current, then synthesizes them and converts them into parameter control signals for the frequency converter to achieve full control over electromagnetic torque.

This way, the motor can maintain low-temperature operation even at low speeds. This frequency conversion technology can suppress the inevitable noise and harmful harmonics in standard inverters. Adopting a new generation of proprietary vector variable frequency control, which converts DC to AC, improves high-temperature resistance, has higher conversion efficiency, saves energy consumption, and enhances reliability.

UD-VFD Series Principle

The Variable Frequency Drive (VFD) air compressor takes the user-side system pressure as its control object, forming a closed-loop control system composed of an inverter, pressure sensor, and VFD motor. The VFD working pressure can be directly set via the operation panel. The sensor detects the system pressure and converts it into a 4~20mA current signal to provide feedback to the controller. The controller compares the PID calculation with the working pressure under the system's VFD setting, thereby controlling the output frequency of the inverter and changing the motor speed to ensure that the output precisely matches the user's air demand, achieving the goals of constant pressure air supply and energy saving.

Product Features

- VFD motor adopts international brand frequency drive;

- Advanced full frequency conversion structure and system;

- Advanced vector control technology;

- VFD soft start, less impact on the power grid, more reliable operation, longer lifespan;

- Energy saving, reducing energy consumption by about 30%~50%;

- Constant pressure air supply, pressure fluctuation can be stabilized within ±0.01Mpa, effectively improving air source quality;

- Lower noise level, about 3 to 7 dB lower than traditional compressors.

Energy-saving Mainframe

- UNITED OSD mainframe is highly recognized in the air compressor industry for its exquisite design and precise manufacturing.

- Adopting screw rotors with large diameter and balanced length-to-diameter ratio, optimized for higher efficiency based on the new fourth-generation rotor profile, so that the contact surface, contact line, leakage triangle, and hydrodynamic properties of the rotor achieve optimal performance, further improving volumetric efficiency. This screw rotor thus has high adiabatic efficiency and low power consumption.

- Utilizing imported large heavy-duty bearings and a unique bearing layout, which greatly enhances load capacity while ensuring bearing rigidity, extends service life, and maintains high reliability even under extreme conditions.

- The spiral groove lip shaft seal, combined with a shaft sleeve made of advanced bearing steel, ensures the wear resistance of both the shaft seal and shaft sleeve. The shaft seal has a pumping function, high reliability, and leakage resistance.

Cabinet Structure Design

The cabinet structure is divided into a cooling chamber and a heating chamber for better heat dissipation. All functional components are located in the cooling section to extend their service life.

The reasonable layout design, which has obtained a national patent, integrates electrical mechanisms, is easy to operate, and can be installed on-site without a foundation. Internally, the cooling and heating chambers do not affect each other, expanding the internal space of the cabinet. Optimized internal air circulation ensures comprehensive cooling of all functional components, extending their service life. The exterior adopts a closed, detachable enclosure with built-in high-quality flame-retardant sound-absorbing sponge, effectively reducing noise.

This structural design not only meets environmental protection requirements but is also easy to use.

Wearing Parts

Particulate Air (HEPA) Filtration:

Heavy-duty air filtration system, with filtration accuracy up to 99.9% for particles larger than 3μm. Suitable for various heavy dust environments.

Oil Filter:

Donaldson oil filter, with high clean filtration grade, effectively protects the main engine bearings for safe operation and extends the main engine's service life.

Oil-Gas Separation System:

European-designed oil-gas separation element, glass fiber filter material, long life, higher efficiency, no frequent replacement required. The aggregate separation element works in conjunction with the oil return device to effectively recover and circulate lubricating oil, preventing oil overspray and ensuring compressor exhaust.

All-new Temperature Control and Oil Filter Combination Valve

This patented design integrates the temperature control and oil filter valves, making internal piping connections simpler, with fewer leakage points, and reducing the incidence of failures. More importantly, it further reduces pressure drop, is more energy-efficient, and avoids obstacles such as pipe vibration, breakage, and leakage that can occur when the oil filter base and temperature control valve are installed separately.

Temperature Control Valve

Powered by British AMOT

Precisely controls the oil return temperature at 65°C. Excessive oil return temperature can damage the oil film, leading to oil deterioration, reduced cooling and sealing performance, and easy carbon buildup; if oil temperature is too low, water separates from the air, the oil emulsifies and deteriorates, affecting the service life of the main engine. Therefore, the temperature control value is a key guarantee for the stable operation of our compressor.

EPC Intelligent Control System

UNITED OSD compressors are equipped with an electronic pressure controller (EPC) to ensure automatic and intelligent operation of the machine. The intake valve controls the discharge pressure between the upper and lower limits of the preset pressure by detecting sensor data such as discharge pressure and temperature, outputting stable pressure. When the compressor idles for too long, the system will automatically stop and restart when air supply is needed, achieving both constant pressure output and energy saving. At the same time, the system can quickly diagnose all on-site faults during operation, maximizing the reliable operation of the compressor and extending its service life.

Local Control

- Chinese and English display languages, touch keys, intuitive, fast, and convenient menu operation.

- Users can preset and control delay times for star-delta switching, startup, loading, shutdown, overpressure, etc., during operation.

- Allows users to view and manage on-site faults.

- Users can store and search historical faults by classification type and occurrence count.

- Internal calendar has accurate time and allows adjustment.

- Users can cumulatively store running time, loading time, unloading time, and filter service time.

- Users can view all preset parameters and accumulated time at any time during operation.

- Users can modify and store parameters to preset values as needed.

Linkage Control

Users can set one compressor as the central unit, and other units as auxiliary or standby units (up to 16 units), forming a linkage control of multiple compressors to ensure economical and stable air supply. It can also automatically adjust the start/stop sequence of each compressor using EPC, balancing the accumulated operating time of each compressor.

Remote Control

Distributed Control System (DCS) remotely controls start-up, shut-down, fault output, and warning signals through passive dry contacts.

Main Computer Control

- The main control computer remotely interlocks and controls two or more compressors, collects and displays on-site signals, and coordinates control and computer operations. By setting host computer parameters, users can obtain comprehensive management of compressor units at any time, and get stable compressed air within the set pressure range.

- Collects and displays a large amount of on-site data

- Vivid graphical interface

- Monitor equipment operating status

- Records important data to the database

- Automatically generates data history reports for future analysis

- Compressor controller operating parameter settings

- Trend curves for parameters such as pressure and temperature

- Real-time and historical alarms

- Operation is permission-secured. A password is required for basic operations.

- Single compressor unit test

- Compressor wear parts maintenance or replacement reminder

UNITED OSD compressors provide various PLC system centralized control solutions according to actual user needs, realizing human-machine interface through IPC, LCD, and configuration software, communicating with DCS in the user's system for remote monitoring, integrating multi-set control capabilities and independent robust development capabilities.

Variable frequency drive technology and ideal energy-saving effects

With UNITED OSD variable frequency drive screw air compressors, you don't need to worry about complex electrical installation and programming. The compressor unit is fully assembled before leaving the factory; it works immediately after power-on. It continuously detects pressure changes in the air system and precisely adjusts the speed through a powerful EPC, always keeping the outlet air consistent with the user system's demand. The EPC calculation response time is in milliseconds, and speed correction is completed within 3ms, accurately controlling the outlet air pressure within 0.1bar. Our built-in filters ensure the safe and reliable operation of the inverter. During use, you don't need to worry about problems like "harmonics" or "radio frequency interference." The dedicated Automatic Energy Optimization (AEO) function ensures that the inverter accurately provides the minimum power to the motor according to the actual load. It can save up to 10% electricity and reduce compressor noise.

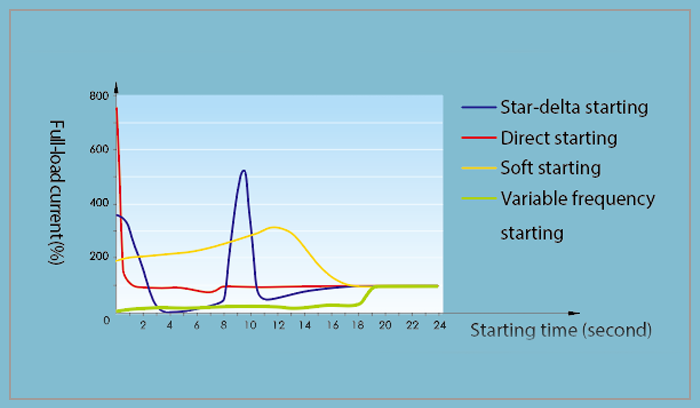

Startup and Operation

This diagram shows a comparison between several startup modes. It is observed that the inverter slowly accelerates startup, which is more stable than soft start and avoids peak currents. After reaching the rated pressure, the inverter performs stepless speed regulation, tracking the air output through pressure detection, and delivering the required airflow without changing pressure, completely eliminating the energy waste of loading and unloading fixed-speed compressors.

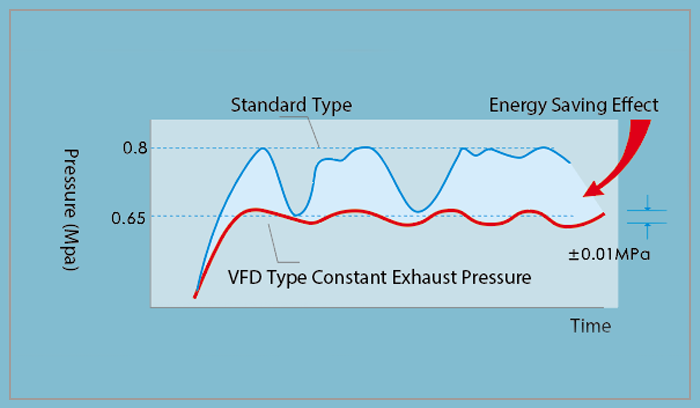

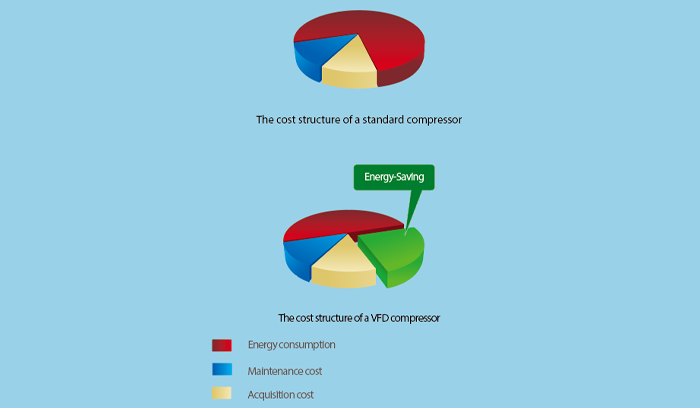

Constant Pressure Energy Saving

This diagram compares the operating pressure of standard compressors and variable frequency drive compressors. It is observed that standard compressors frequently load and unload between the minimum required force and above 1.5bar. Compared to frequency-controlled pressure stable at the minimum required pressure (per 1bar pressure), producing 1.5bar pressure wastes 10.5% more energy (increasing power consumption by more than 7%). Furthermore, zero air standby consumes 45% more no-load energy during unloading. Therefore, constant pressure air supply saves energy during loading and unloading, extends the service life of the unit, and eliminates adverse factors of unstable pressure affecting user production.

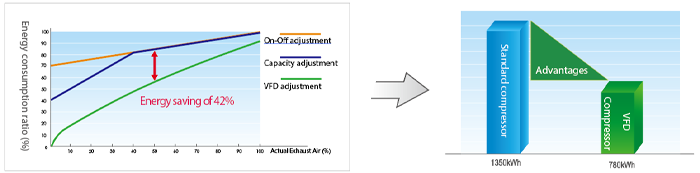

For example, a compressor with an annual energy consumption of 250KW (using 50% air volume) and an operating time of 6000h/year.

Comparing volume adjustment with standard compressors; variable frequency compressors can reduce electricity consumption by 42%, saving approximately 570,000 kWh of energy annually. (An appropriately sized air receiver tank must be installed to enhance energy-saving effects.)

Cost Comparison

Modular Vector Inverter

UNITED OSD UD-VFD series compressors are equipped with a new generation of modular high-performance inverters customized by international OEMs according to UNITED OSD requirements. Development, design, and manufacturing follow the principle of complete compatibility with UNITED OSD compressors; R&D and production of compressor characteristics, hardware, software, power modules, printed circuit boards, and accessories ensure reliable quality. The inverter can automatically match the motor, read and check motor parameters in real-time, ensuring optimal matching between the inverter and the motor.

- The motor is disconnected from the load during the inverter's initial setup. The inverter can automatically unload the motor.

- Unaffected by power system fluctuations, if the input voltage is -10%, the inverter will automatically compensate the output voltage to the motor's rated voltage.

- An inverter can drive multiple standard compressors for linked control.

- Optimized fault protection, achieving comprehensive protection from the inverter to the motor.

- Optimized fault protection, achieving comprehensive protection from the inverter to the motor.

- Multi-speed and built-in PLC functions automatically control multi-frequency logic.

- Stable output frequency, strong anti-interference ability; certified tests from various laboratories.

Personalized functions:

- Starting Torque: 0.5HZ/150% (SVC).

- Speed Regulation Range: 1:100, with significant energy-saving effect.

- SFV, constant speed accuracy, up to +/-0.5%.

- Overload Capacity: 150% rated current for 60s, 180% rated current for 1s.

- Allows live inspection of peripheral devices while powered on, such as grounding and short circuits.

UNITED OSD VFD screw compressor can precisely change the motor speed based on changes in gas consumption, under the principle of stable exhaust pressure; the compressor outputs the required air volume, consuming only the energy required for the output of compressed air, achieving energy-saving purposes. Future energy cost savings will significantly exceed the value of the compressor.

Patent Protection

Through continuous R&D investment, the pace of product development and new technology application has accelerated. Currently, UNITED OSD has registered nearly a hundred national patents, covering key compressor technologies, integrated layouts, and integrated component improvements. These patents have solved a series of compressor problems, such as internal temperature rise under different operating conditions and maintenance difficulties. Through unique design and integration, the equipment can better meet usage requirements and services, comply with environmental protection requirements, fully demonstrating the excellent quality of the products.

Quality Assurance

In 2003, UNITED OSD compressors passed ISO9001 Quality Management System and ISO14001 Environmental Management System certifications. The company strictly adheres to Crosby's

Single-stage VPM (VFD+PM) Screw Air Compressor

Contact Us

mail@sunc.cn

021-69176699

Category: