- All

- Product Management

- News Information

- Introduction Content

- Company Network

- FAQ

- Company Video

- Company Album

Smart Control System

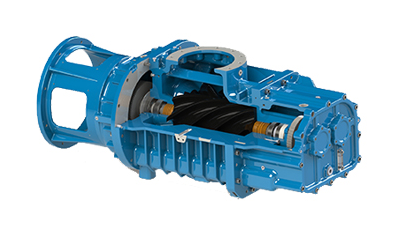

Currently, Roots blowers are still widely used in various industries. It is a reliable and straightforward design that has solved problems in various fields of process applications and made significant contributions to industrial development. However, the inherent high energy consumption and high noise characteristics of Roots blowers are incompatible with the demands of today's users. The entire society pursues green environmental protection, energy conservation, and emission reduction. In contrast, oil-free screw compression technology brings environmentally friendly blower products, replacing the outdated and inefficient Roots blower technology. Oil-free screw compressor technology has been fully verified by the market and applied to low-pressure blowers. The design and manufacturing experience of oil-free screw compressors also make oil-free screw blowers stable and reliable. Screw blowers are developed from oil-free screw compressor technology and have three prominent features: low noise, oil-free air, and high efficiency.

Product Features

- Utilizes world-leading molding production lines to develop stable air compressors.

- Advanced coating technology reduces the main unit gap, improves volumetric efficiency, and effectively protects the main unit's lifespan.

- Uses world-renowned FAG bearings to ensure reliability.

- Adopts National Standard Grade 5 precision synchronous gears and transmission gears to ensure reliability and extend service life.

- Labyrinth seals and helical sealing components ensure oil-free air reaches Class 0.

- Exceptional lubrication and oil discharge channels ensure adequate lubrication and cooling of bearings and gears, while also improving compression efficiency.

Low Noise

Roots blowers lack internal compression, which leads to high-pressure air from the pipe network backfilling into the compression chamber during discharge, creating an air impact, generating high and low-frequency air noise, and significant equipment vibration. Screw blowers have internal compression, and their compression chamber discharge pressure is close to the pipe network pressure, resulting in smooth discharge and significantly reducing equipment vibration and noise. The noise of screw blowers is concentrated in the high-frequency range, which can be addressed through silencers and noise reduction measures. Therefore, the overall noise of screw blowers is 30dB(A) lower than that of Roots blowers.

After analyzing the sound source spectrum, professional customized intake and exhaust silencer designs greatly reduce the noise transmission of oil-free screw compressors to the external environment. The entire oil-free screw blower is fully sealed with a soundproof enclosure. The air inlet, after special noise-reducing inlet treatment, enters the inner cavity. Noise transmission from the inside to the outside is minimized.

The exhaust silencer contains no asbestos, PE cotton, or other sound-absorbing materials. Noise reduction is achieved through acoustic design. Therefore, there is no secondary pollution to the air, ensuring clean air.

- PLC intelligent control, 6-inch color LCD touch screen display.

- User-friendly operating system.

- The controller features start-stop control, frequency conversion control (VFD version), real-time monitoring of exhaust pressure, exhaust temperature, lubricating oil pressure and temperature, maintenance time, fault warning, fault recording, and other functions.

- RS485 connection, interlock control, and remote control. The VFD version supports signal control of dissolved oxygen concentration (DO).

- Standard equipped with a wireless internet module for remote access from PCs, Pads, and smartphones, allowing you to check operating status anytime, anywhere.

Efficiency

Compared to traditional Roots blowers, UNITED OSD oil-free screw blowers offer higher efficiency based on their technical principles.

See the P-V performance diagrams for Roots and screw blowers below.

4→1 Suction process. As the Roots rotor rotates, air is drawn in until the inlet closes.

1→2 External compression process. It can be divided into two methods. The Roots rotor continues to rotate, and the volume of the enclosed space remains unchanged, thus there is no internal compression.

Until the enclosed space is suddenly exposed to the outlet port, the air pressure in this part rises as it is compressed by the pipe network.

2→3 Discharge process. As the Roots rotor rotates, the compressed air is released into the pipe network.

UNITED OSD Oil-free screw blowers save energy compared to Roots blowers

4→1 Suction process. As the screw rotor rotates, the volume of the helical groove gradually increases, and air is drawn into the blower until the inlet closes.

1→2 Internal compression process. The inlet has already closed, and the outlet has not yet opened. Due to the helical design, the helical motion causes the volume of the enclosed helical groove to become progressively smaller, leading to internal compression and pressure rise.

2→3 Discharge process. As the rotor rotates, the exhaust port opens, and compressed air is discharged from the blower.

Under the same airflow and pressure conditions, screw blowers consume significantly less power. In the diagram, the green part represents the energy saved. Compared to traditional Roots blowers, screw blowers save 35% energy. The higher the pressure, the more significant the energy saving, with an average saving of 20%. Coupled with precision design and manufacturing, intelligent control, and variable frequency drive, oil-free screw blowers are 20%-50% more energy-efficient than Roots blowers.

The UNITED OSD oil-free screw blower is a skid-mounted package unit. The blower host, motor, gearbox, intake filter, intake and exhaust silencers, shock absorbers, safety valve, exhaust check valve, starter cabinet, control system, inverter, soundproof enclosure, and all other components are integrated and installed on the chassis. All units filled with lubricating oil have completed testing before leaving the factory. There is no need to embed expansion bolts in the installation foundation. It only requires a smooth and sturdy concrete floor for installation. Connect the exhaust pipe network and plug in the power cord, and the blower can be started for use.

It is recommended to install a butterfly valve on the exhaust pipe of each blower to easily cut off the connection with the pipe network for equipment maintenance. For the relationship between branch pipes and main pipes, it is recommended to use a 'Y'-type tee instead of a 'T'-type tee to reduce pressure loss.

The optional outdoor rainproof kit allows users to install the blower system near the point of use, such as next to an oil sump.

Application Areas:

In many environmental protection and industrial production fields, blowers are required to generate low-pressure air. Screw blowers are used for wastewater discharge, representing environmental protection. Municipal and industrial wastewater (including those from textile printing and dyeing, leather, medicine, chemical, paper-making, aquaculture, slaughtering, etc.) must be treated to meet standards before being discharged into natural water bodies or recycled. In the wastewater treatment process, one of the key steps is oxygen supply for biological treatment, which is the aeration process.

The energy consumption of the oxygen supply biological treatment system accounts for 50%-55% of the entire sewage treatment plant. There is significant room for reducing energy consumption in oxygen supply biological treatment, and the selected UNITED blower will directly bring objective economic benefits.

Desulfurization and Denitrification

In thermal power plants, steel, glass, chemical, and other factories, many boilers are in operation, and their flue gas contains a large amount of sulfur, nitrates, and other substances, seriously polluting the atmosphere. Therefore, flue gas must undergo desulfurization and denitrification treatment before being discharged into the atmosphere. In desulfurization and denitrification facilities, high-pressure blowers are required for the oxidation process.

Fermentation, pneumatic conveying, air knife, deformation

Oil-free screw blowers are widely used in bioengineering, pharmaceuticals, cement, steel, power generation, grain processing, textile, and other industries, making significant contributions to reducing energy consumption per unit of output value.

Oil-free Screw Blower

Contact Us

mail@sunc.cn

021-69176699

Category: