Products

Industry application

Metallurgical Industry

Automobile Manufacturing

Electronic Semiconductor

Food And Beverage

Pharmaceutical Manufacturing

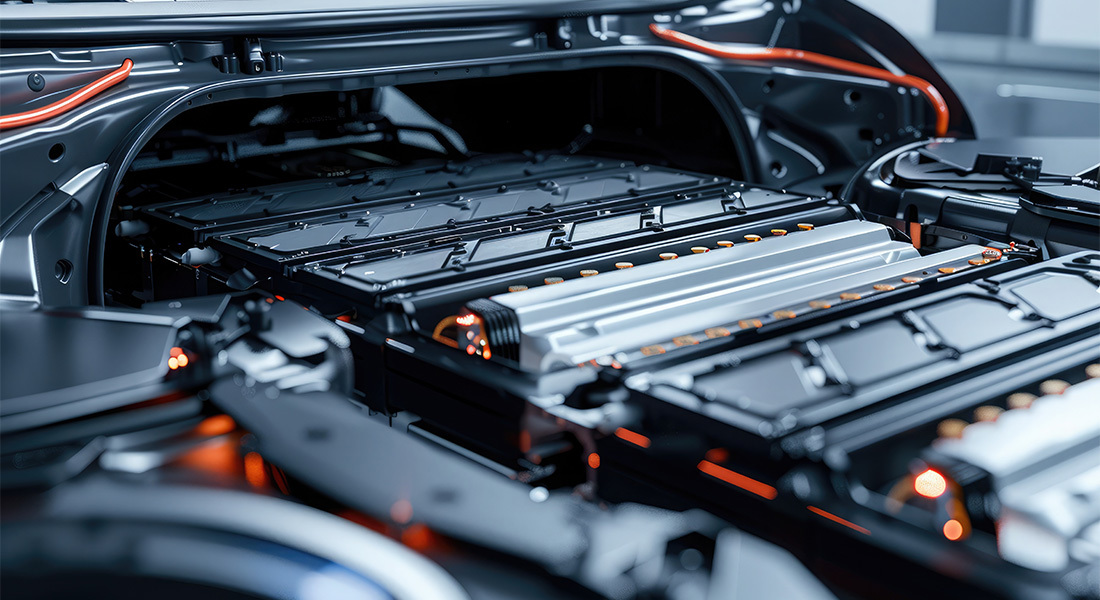

New Energy

About us

Founded in 2002, Shanghai United Compressor Co., Ltd. is dedicated to developing and manufacturing industrial high-efficiency compressors and core components, specializing in energy-saving technologies for compressed air systems and providing related services.

In 2013, United entered a joint venture with Hitachi Group, a Fortune 500 company, which is a well-known enterprise founded in 1910 with over 100 years of experience in compressor manufacturing. The J/V cooperation not only complements each other's product vacancy but also enhances each other's ability to design, production, quality control and service. As a result, United rose to become a leading air compressor manufacturer in China.

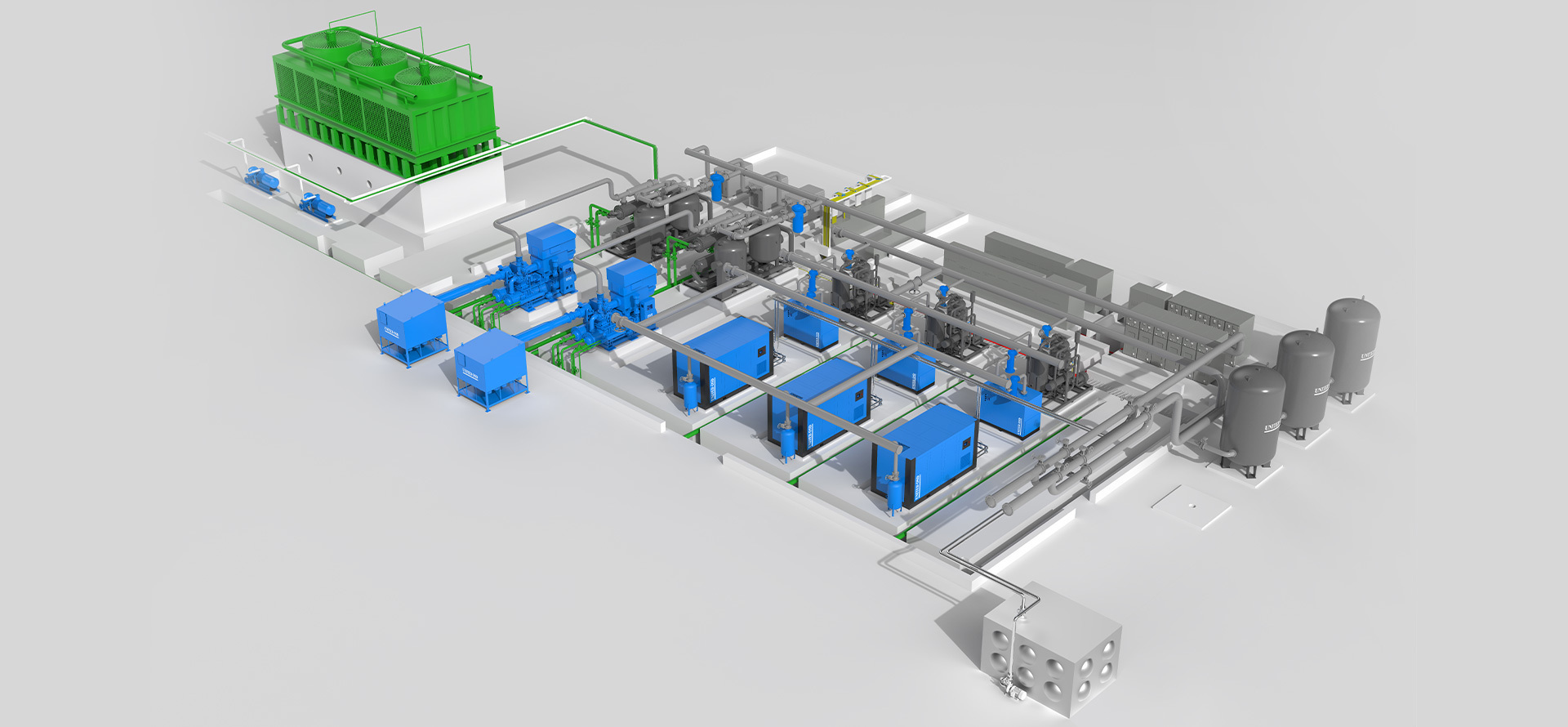

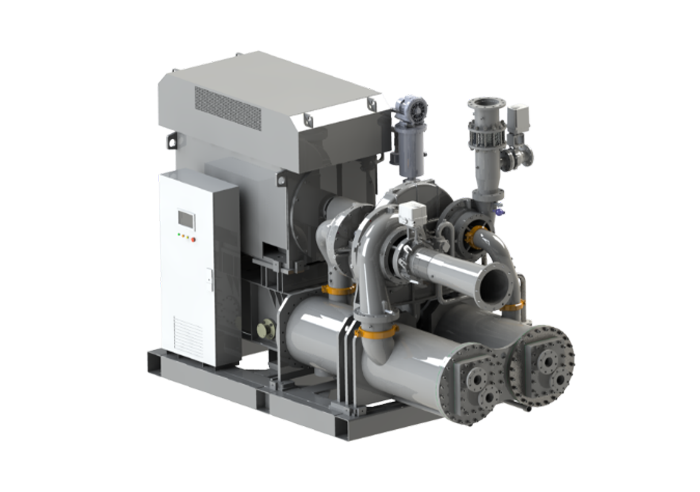

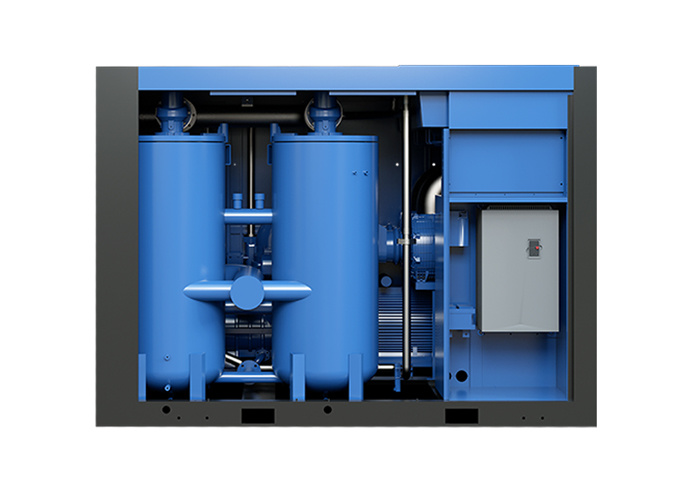

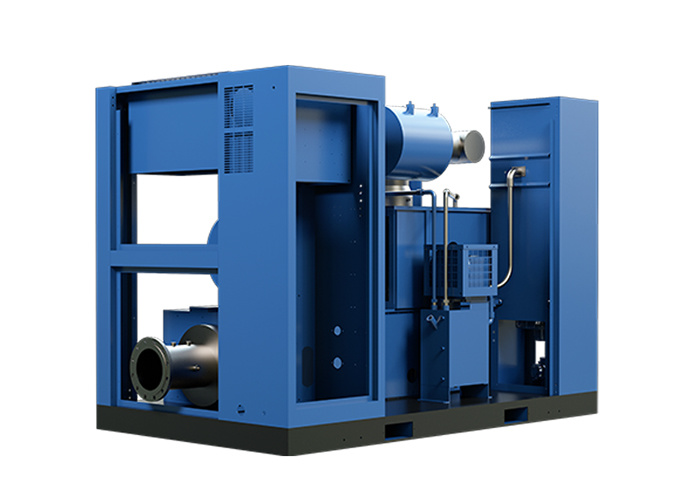

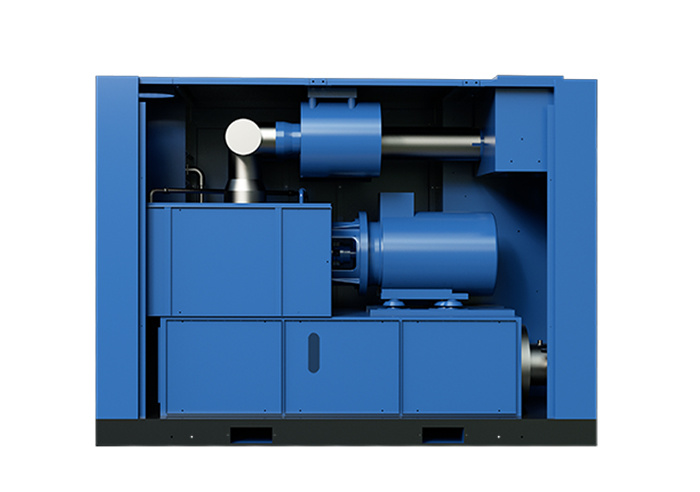

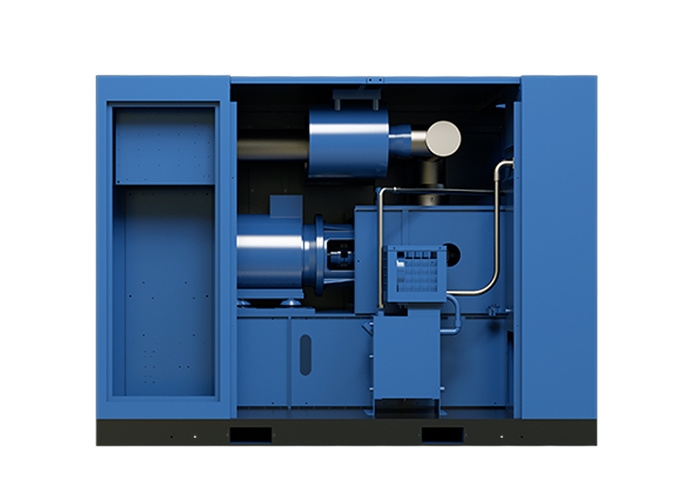

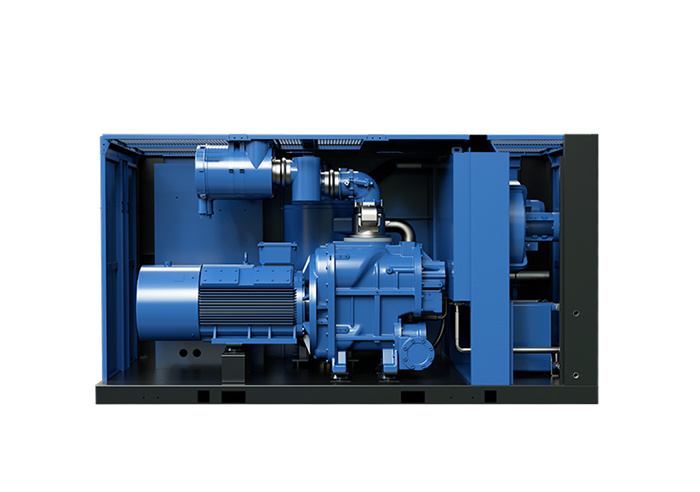

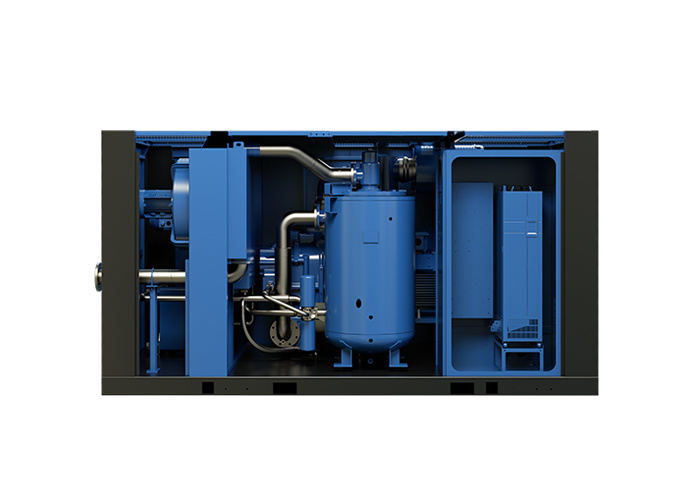

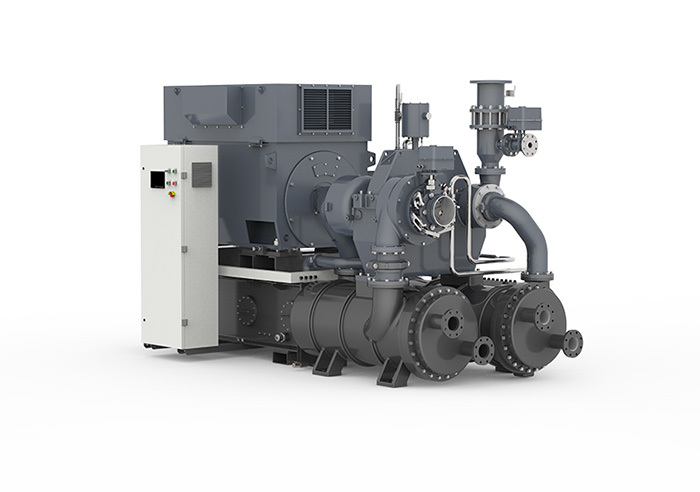

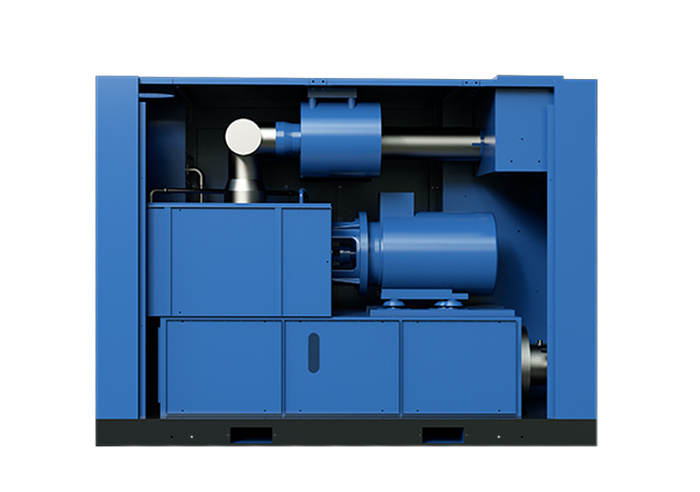

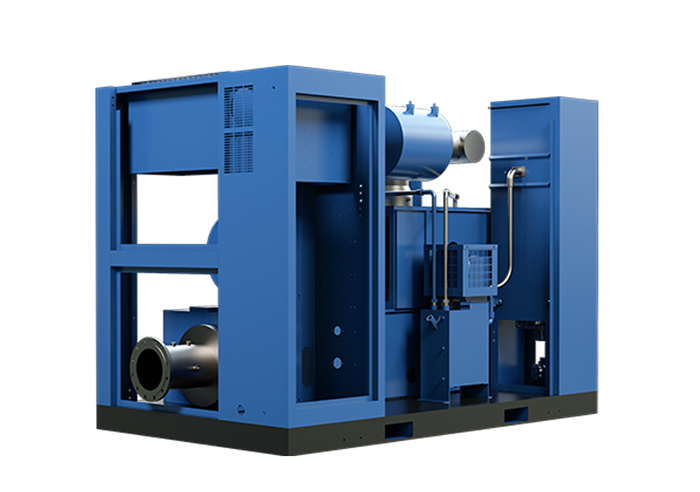

Adhering to the concept of "energy-saving and environmental protection”, United has successively launched product lines including micro-oil/oil-free screw compressors, centrifugal compressors, high-efficiency air compressor stations, and scroll compressors. On this basis, it has also developed industry-specific products as well as special compressors. United is one of the few domestic companies with the ability to independently research and produce compressor mainframes.

Unitec is committed to becoming a world-leading supplier of compressed air system solutions.

Service and Support

Unites Compressors is committed to building a network of specially trained service experts and teams to provide you with installation, commissioning, maintenance and repair services for combined compressors at any time.

Currently, Unites has established 100 domestic network service stations in China, and is gradually improving its overseas marketing service network.

The goal of Unites Compressors is to ensure a high level of operational safety for our customers and to maximize the availability of compressors through preventive maintenance, especially in challenging environments such as Atmosphere Leakage (ATEX) or coastal areas.

There is no better choice than our service and genuine spare parts!

Professional service

Free training

Monthly inspection

Worry-free after-sales

News Center

News

2025-04-11

News

As the Hanover Stage Concludes, UNITED Embarks on a new Journey of Global Industrial Empowerment.

2025-04-05

News

2025-04-03